Ensuring Excellence in Every Printed Circuit Board Assembly

DCA manufactures high-quality, reliable, and high-performance Printed Circuit Board Assemblies (PCBA) by utilizing a comprehensive suite of inspection and testing services. Our state-of-the-art PCBA inspection and testing processes are integrated at every stage of electronic manufacturing, ensuring defect-free production, enhanced product consistency, and full compliance with IPC-A-610, IPC-J-STD-001, and in accordance with Quality Systems defined by ISO 9001, ISO 13485, and IATF 16949. As a leading Electronics Manufacturing Services (EMS) provider, DCA Manufacturing serves industries such as Defense, Aerospace, Industrial, Medical and Automotive, ensuring that every PCBA meets the highest quality standards.

Comprehensive PCBA Inspection & Testing Solutions

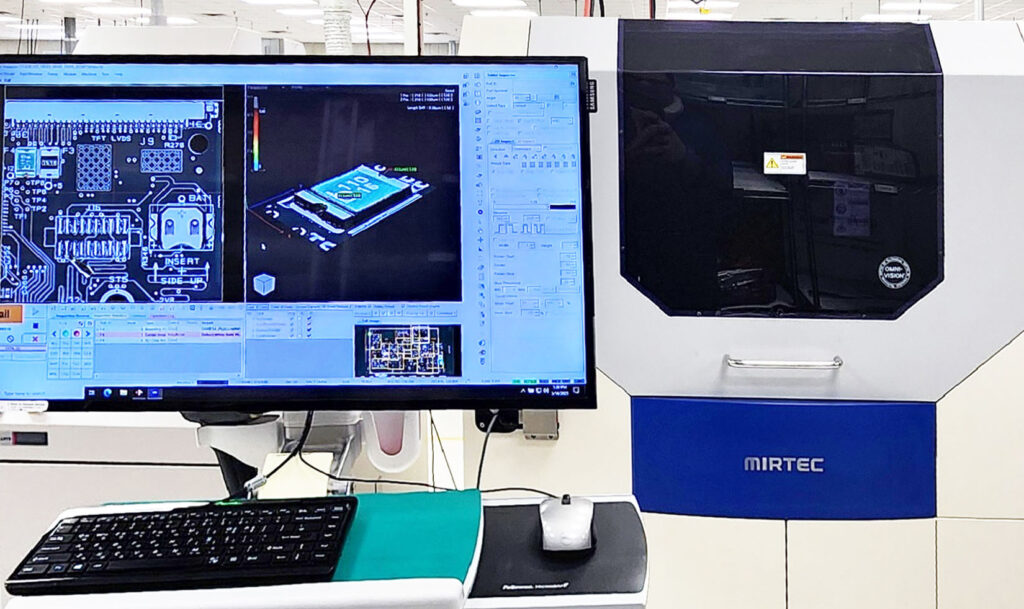

Automated Optical Inspection (AOI)

- AOI technology is a vital step in quality control, utilizing high-resolution imaging and pattern recognition to detect soldering defects such as cold solder joints, insufficient solder, and solder bridging

- Also identifies component misalignment, wrong component, incorrect polarity, and missing components

- Enhances defect detection rates and overall product integrity in PCBA manufacturing workflow

X-Ray Inspection for Hidden Defects

- Provides a comprehensive analysis of QFNs, BGA (Ball Grid Array) and micro-BGA solder joints in complex PCBAs

- Detects solder voids, insufficient solder, and internal defects

- Multi-layer PCB analysis for enhanced quality assurance, ensuring robust electrical connections, particularly in high-reliability applications

In-Circuit Testing (ICT) for Electrical Integrity

- Verifies electrical integrity and component functionality, detecting potential issues before final assembly

- Includes verification of component values such as resistors, capacitors, and ICs using enhanced boundary scans

- Detects open and short circuits and power integrity analysis

- Early-stage detection through ICT reduces rework costs and improves overall product yields

Functional Testing (FT) – Application Performance Validation

- Simulates real-world conditions to ensure that every PCBA meets performance expectations

- Our FT capabilities include 100% functional verification of assembled boards, custom-designed test fixtures and software, load testing, power cycling, and environmental stress testing

- With FT testing, we mitigate the risk of field failures, ensuring product reliability and deployment readiness

First Article Inspection (FAI) – Ensuring Compliance Before Full Production

- First Article Inspection (FAI) verifies component and material accuracy, compliance with IPC and J-STD standards, and dimensional validation using precision measurement equipment

- Comprehensive documentation and traceability are maintained to ensure alignment with customer specifications before full-scale production begins