DCA provides fully assembled, high-reliability electronic systems through our comprehensive System Integration & Box Build services that include the Printed Circuit Board Assemblies as well. Whether you need a simple control enclosure, a complex cabinet assembly, or a fully integrated product ready for end-user deployment, our capabilities span every stage of the manufacturing cycle—from PCB assembly, and system integration to final testing and packaging.

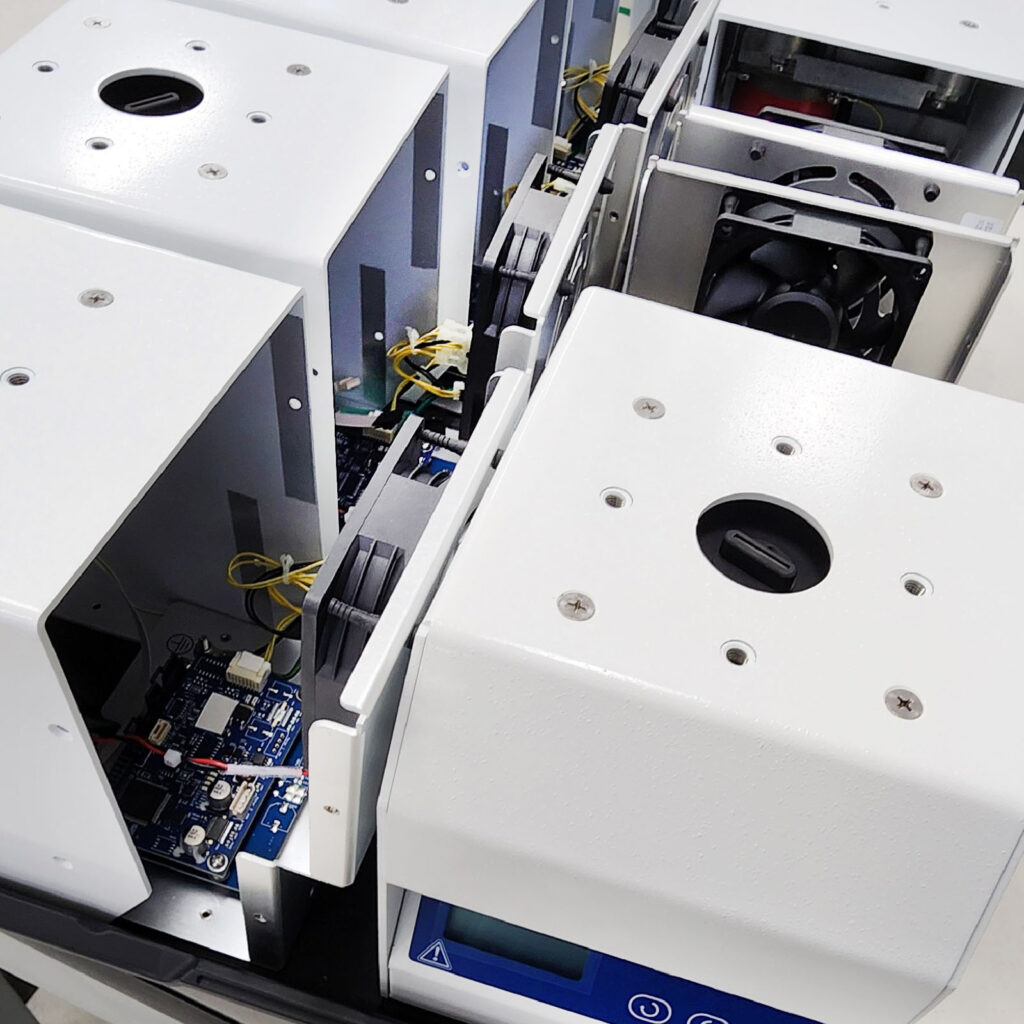

System Integration & Box Build refers to the process of taking individual components; such as printed circuit board assemblies, wire harnesses, power supplies, displays, and enclosures and assembling them into a complete, functional electronic system. The result is a market-ready product that arrives fully tested, labeled, and ready for immediate deployment.

Key Elements of System Integration & Box Build

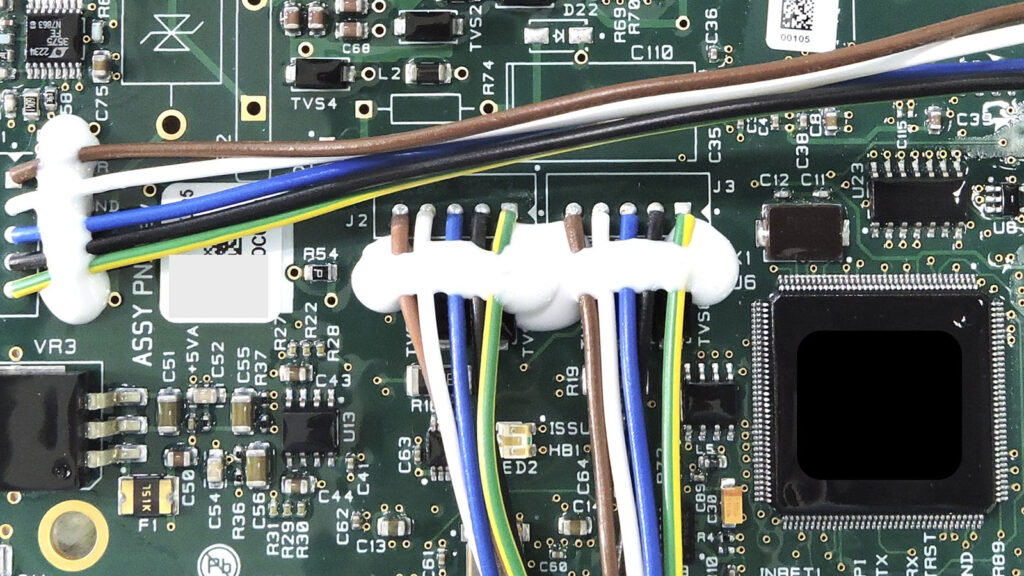

- Printed Circuit Board Assembly (PCBA) – Comprehensive range of PCB assembly solutions including rigid, flex and rigid-flex PCB assemblies with surface mount and through-hole component placements

- Conformal Coating & Potting – Application of protective silicone, polyurethane, and acrylic coatings and/or single or dual part potting materials to safeguard assemblies from moisture, dust, chemicals, and vibrations—especially critical for industrial, automotive, and aerospace applications

- Enclosures & Mechanical Assembly – Installing and connecting completed PCBAs into custom enclosures or sub-assemblies including displays, LCD, and switches etc.

- Wire Harness & Cable Assembly – Managing the power, data, and signal connections within the enclosure to ensure seamless system operation

- Final Testing & Quality Checks – Conducting functional, environmental, and regulatory testing to confirm product performance and compliance

- Logistics & Packaging – Labeling, barcoding, and shipping finished units ready for distribution or end-user use