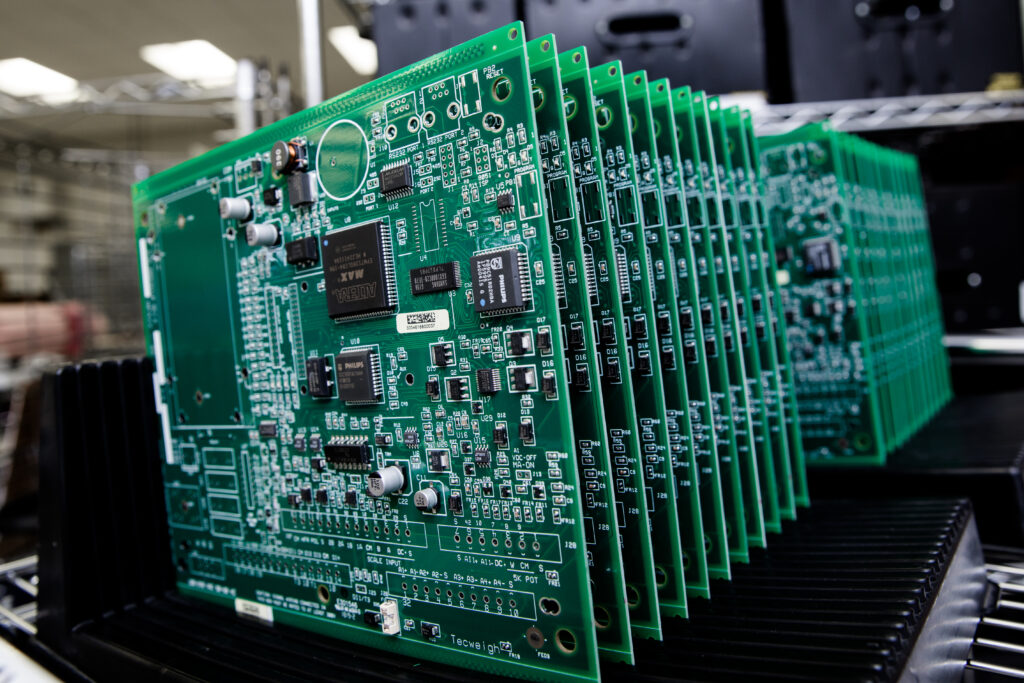

DCA provides complete turn-key solutions that simplify the production process, ensuring precise execution from concept to delivery. Our expertise spans across design, engineering, material sourcing, manufacturing, testing, and logistics, allowing businesses to optimize efficiency, cut costs, and achieve consistent, high-quality results without managing multiple vendors.

Key Benefits of DCA’s Turn-Key PCBA Solutions

Single Point of Contact

- Eliminates the hassle of coordinating multiple vendors

- Streamlines communication and project management

- Reduces delays and misalignment caused by third-party suppliers

Cost Efficiency & Lean Manufacturing

- Consolidated services minimize overhead and labor costs

- Optimized procurement strategies for cost-effective material sourcing

- Lean manufacturing principles to reduce waste and inefficiencies

Accelerated Time-to-Market

- Fully integrated workflow speeds up production timelines

- Rapid prototyping and agile volume production for faster product launches

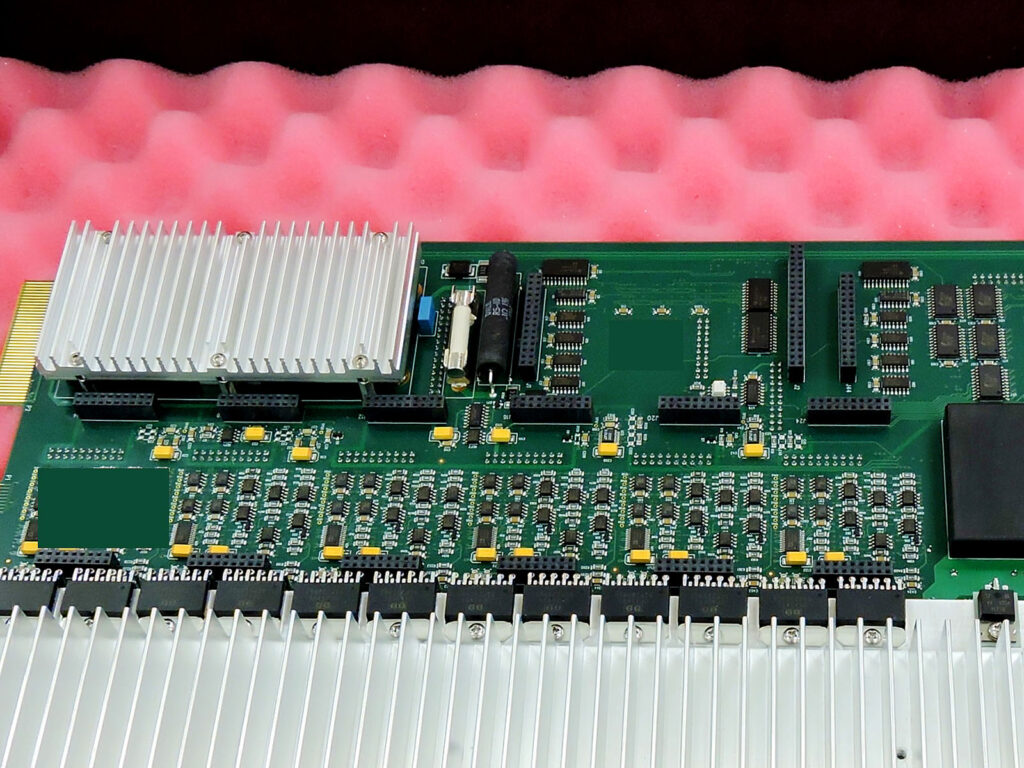

Superior Quality & Compliance Assurance

- Strict quality control from start to finish

- Adherence to quality and compliance regulations

- Minimized risks related to defects, and rework

Scalable & Flexible Production

- Supports NPI, prototyping to full-volume manufacturing

- Customizable solutions tailored to your unique business needs

- Easily adapts to shifting market and customer demands

Innovative Manufacturing Technologies

DCA embraces the latest technological advancements to revolutionize the manufacturing process. Our smart manufacturing techniques allow for optimum efficiency, real-time monitoring, and predictive maintenance that keep our production lines operating at peak performance. By integrating precision automation and workflows, we minimize human error, enhance accuracy, and ensure consistent quality output.